…but before that…

I replaced the Plasma V2 with a Plasma MM2 that I had. Turns out that the P2 was the core of all my controllability problems. Once I installed the MM2, it was a whole ‘nuther ballgame. No more crazy spikes or sluggish control inputs. It was pretty damn nice actually. 🙂

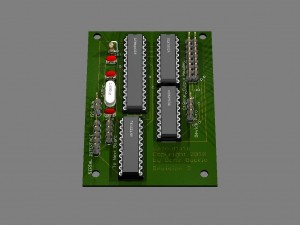

Here’s the board I put together in order to interface the MM2:

What kills me is that this device is no longer available.

Another change I made was to the return springs that were in the pitch axis mechanism. The original springs weren’t up to the task with the amount of weight in the grip & interface box. The stick would stay where ever I let go of it. The springs I use are compression springs that are 2″ long and made from .072″ diameter wire. I changed to a 2.50″ spring made of .080 wire. This made a big difference for a small change. The pitch axis now returns to center the way it should. However, the feel is still a bit weak so I may change that to an even stiffer spring.

Ok, now back to the title of this entry…

I ordered three projector kits on the 31st of December. After an agonizing wait they were finally shipped. Here’s some of the parts:

The kit consists of optics (220mm & 330mm fresnel lenses and a 330mm “triplet” output lens), power panel, 400W Metal-Halide lamp (that the 12 year old in me has christened The Photon Phallus. *snickers*), Mogul base for the lamp, temperature controller for the fan, a fan and a 400W ballast for the lamp. All of this neat stuff is available from DIY Projector Kits (http://www.diyprojectorkits.com).

Be warned, the plans (at least for the one I have, the S-15) are VERY, VERY, VERY vague. If you get one and have questions, either see my build thread on the site (“geneb’s triple threat”) or email me directly. My build thread will do what it can to rectify the captionless pictures that comprise some of the documentation. 😀

On the 23rd, I spent the day doing maintenance work on the ShopBot, including adding a 1/32″ gasket to all the vacuum zones. The gasket drastically improved the performance of the vacuum hold down system. I then got all the parts cut for the projector cases. I used 18mm (3/4″) Baltic Birch.

Here’s the first of two sheets that were cut:

The parts in the foreground with the long slot in the center is the projector top. The slot is the air intake for the lamp cooling fan. It draws air in-between the “cassette” that holds the 15.4″ LCD panel and the cassette that holds the collimating fresnel. You’ll see pictures of these things in the coming days.

Here’s the stack of parts that resulted from yesterday’s run:

The next steps are to mark & drill the case parts for the pocket screws I’m going to use for assembly and make the LCD and fresnel cassettes….

To hold you over till next time, here’s a video I shot of the beta version of the avionics system I’ll be using in the cockpit:

httpv://www.youtube.com/watch?v=1X69mIBtyu0