Most fighter aircraft don’t have seats that move fore & aft like a car seat does. Instead, the seat is bolted in to place and the rudder pedal assembly is built to move in order to adjust for different sized pilots.

In order to do that in my cockpit, I mounted my rudder pedals on a pair of ball bearing drawer slides laid horizontally.

The drawer slides are a little bit over 12″ long.

In order to “lock” the rudder pedals into place, I installed a pair of aluminum plates into the cockpit floor that are drilled to take 1/4″ locking “pins”.

It’s pretty simple, but it does get the job done! At some point I’d like to be able to turn the two bolts I’m using as locking pins into actual pins that can be retracted from the cockpit itself, allowing adjustment without having to exit the cockpit and manipulate them from the front access hatch.

The other project that was finished is the trim & flap wheels:

The wheels have a 12 tooth sprocket and they drive a 48 tooth sprocket that’s connected to a potentiometer. This gives roughly four turns of the wheel to one turn of the pot.

I’m using #25 roller chain for this. It’s similar to bicycle chain, but about half size. The 48 tooth sprockets have travel restricting devices installed in order to prevent the high-torque output of the trim wheel from destroying the end stops in the potentiometers.

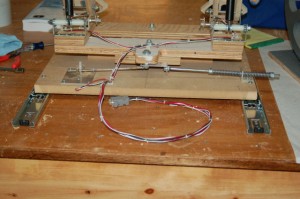

Here’s a pic of it installed in the prototype:

It shouldn’t be too much longer before I actually get to flight test all this stuff. *laughs*

That TQ looks really nice installed. Beautiful work.

Hi,

if I can remember the Me-109 has a trim wheel which moves more than 360 degrees and I suppose you are using a 360deg. rotary potentiometer.

That’s correct. The current setup uses a #25 roller chain to connect the trim & flap wheels to pots. The ratio works out to be about 3-1/2 turns of the wheel to rotate the pot 270 degrees.

g.

Ok, thanks for the answer, in real, you have to make about 20 full rounds to get full flaps.