In doing research for making wiring boards for the EPIC (used in my F-15C project) I discovered a technique for making printed circuit boards (PCBs) that doesn’t involve any etching chemicals.

The process is called PCB Isolation Routing and is done by using a CNC router with a VERY small “V” bit in it. The bit used has a tip diameter of about 0.007″.

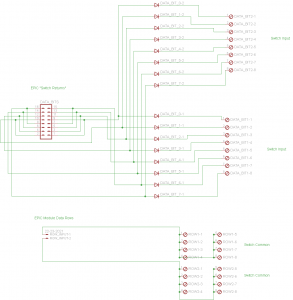

The key to the whole process is being able to generate code to create the PCB. This can be accomplished with the free version of Eagle PCB in combination with a free program called PCB-GCODE

PCB-GCODE is a plug-in for Eagle that will take your board layout and generate the needed code to drive any standard CNC router that understands G-code.

If you head over to this site, you can get a pretty good overview of the process itself.

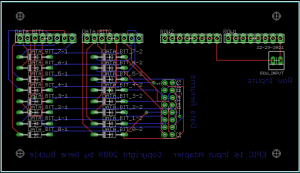

In order to use this process with my ShopBot, I needed to come up with a way to hold down the PCB material while the machine was working on it. Below is the jig I created.

PCB hold down jig

When you add two more hold downs, this jig can hold down a pretty good sized board. The jig itself is 11-3/4″ high and about 13″ wide.

The grooves you can see cut in the right corner are for alignment blocks. They consist of two 6″x3/4″ .125″ thick aluminum bars that are used to locate the PCB material in the lower right hand corner of the jig, where the X & Y “home” is. By leaving the bars in place, you have a repeatable point for locating your material when you flip it if you’re doing double sided boards.

When my double sided PCB stock arrives next week, I’ll put together a video showing how it works using my new EPIC input boards as an example.